Murata Machinery, Ltd.

Special Feature Page

for Sheet Metal machines

Event

Notice of Participation in MF-TOKYO 2025

We are pleased to announce that Murata Machinery and Muratec group will be exhibiting at MF-TOKYO 2025.

With the firm belief that each machine we showcase will be a groundbreaking solution to help our customers overcome their challenges, we have chosen the concept:

“Together, Shaping the Future - Innovation in One Machine”

Through our innovative products and services, we are committed to offering proposals that truly resonate with our customers’ needs.

All of us at the Muratec Group sincerely look forward to welcoming you at the event.

Venue: Tokyo Big Sight, East Hall 5, Booth 5-09

Dates: July 16 (Wed) – July 19 (Sat), 2025

Opening Hours: 10:00 AM – 5:00 PM

Note: Closes at 4:00 PM on the final day

Exhibit Models

Introduction to Our Exhibits

Industry First!

Cutting and Milling — Process Consolidation

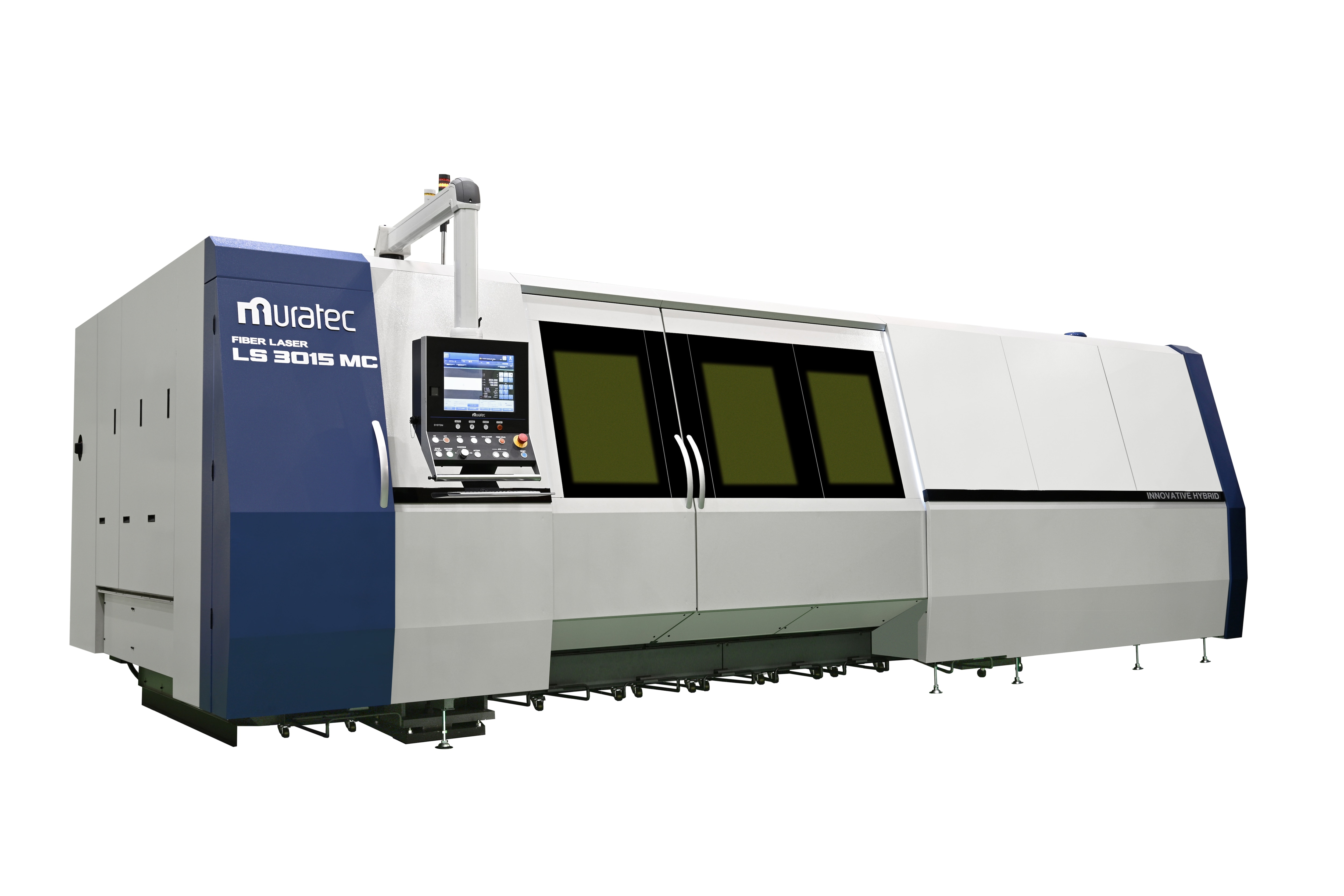

Fiber Laser Combination Machine “LS3015MC”

with Laser Cell Loader & Stocker System “FS3015TM”

We have developed the LS3015MC, a unique fiber laser combination machine that pushes the boundaries of multi-processing by incorporating cutting and milling, especially essential for medium to thick sheet metal.

We will also showcase the new FS3015TM Laser Cell Loader & Stocker System, which enables automated single-sheet loading up to 12mm thickness.

By consolidating multiple processes and enabling extended unattended operation, this system addresses key challenges in manufacturing such as labor shortages, product management, and cost reduction—all with a single machine.

Feature

| Point | 1 |

Space-Saving Design

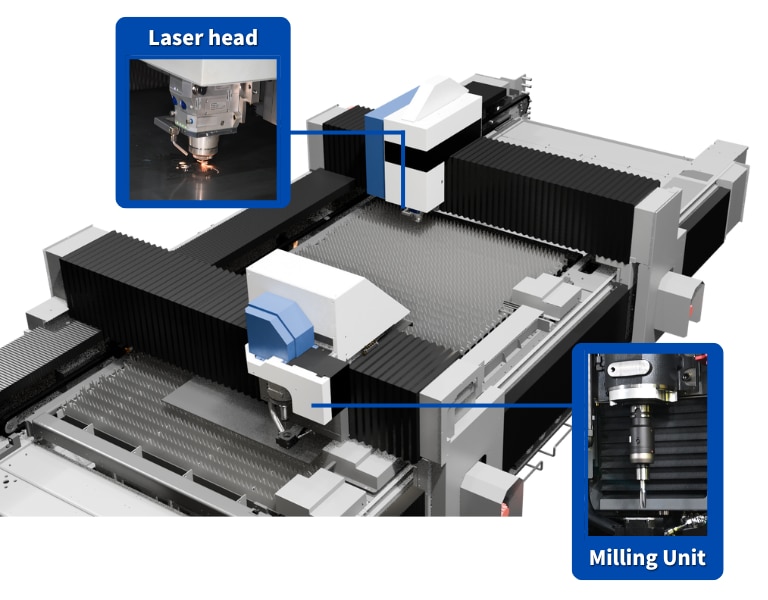

It features a compact layout that integrates two processing units—one for laser cutting and one for milling—within the same space, minimizing installation space requirements.

| Point | 2 |

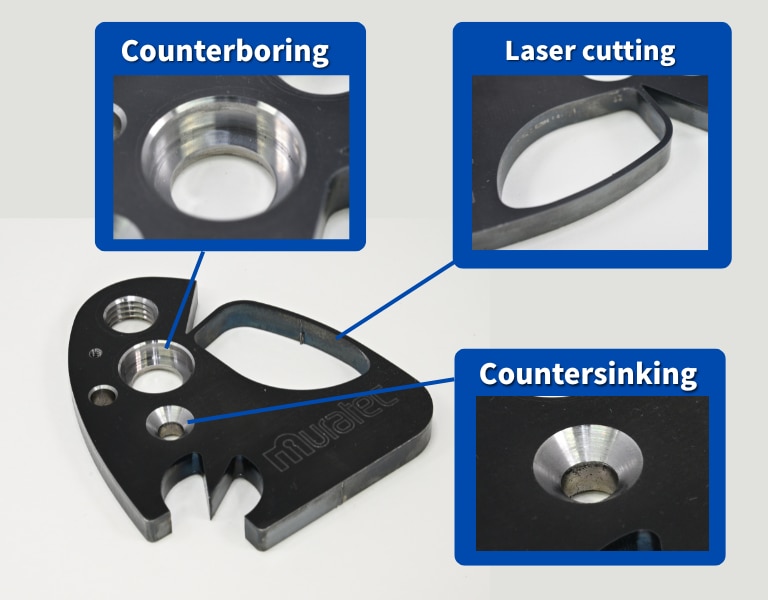

Process Integration

It is equipped with a sheet-holding mechanism that suppresses vibration during processing, as well as a suctioning unit to remove chips and slugs.

These features enable drilling, tapping, countersinking, and counterboring to be performed directly on sluts pallet, all within a single setup.

| Point | 3 |

Thick Sheet Processing

Utilizing a flying optics-type fiber laser unit, we offer combined processing for materials up to 16mm and laser cutting for materials up to 25mm.

For more product details, please contact us.

Easy Operation & Automatic Bending

Bending Robot System

Our robotic system ensures precise and consistent production, independent of operator skill.

Point❶

Bending Robot System

Conventional bending robot systems required advanced robot operation skills for on-site teaching. However, with “MRBS,” correction operations can now be performed through product-driven control.

Point❷

Automatic Tool Tower: TT32

It can store up to 32 meters worth of tools — 12 cassettes for upper tools and 20 cassettes for bottom tools. Shortening tool change time enables higher machine utilization and reduces operator workload.

Point❸

Robot-Dedicated CAM: CAMPATH Bend Robot

No complex operation is required. It generates the robot’s motion path by specifying gripping positions for loading, bending, and regripping processes, checking for interference, and verifying reachability of robot postures.

DX and Visualization

Connected Operation Support System

"ProcessNet Portal" is a cloud-based support service that facilitates digital transformation (DX) in manufacturing.

It is a connected operation support system designed with the customer in mind, enabling users to "know instantly, know more, and know deeply" about machine operating conditions.

By leveraging IoT and ICT technologies, it supports early recovery from issues and preventive maintenance, helping customers maintain smooth and efficient operations.

More

Data Solution Zone

This is a new automated sheet metal processing data solution that enables unified automatic processing of developing, blanking and bending—as long as 3D design data is available.

By utilizing SCPX, which consolidates all the necessary information for sheet metal processes from 3D data, we propose a solution that reduces the need for manual data creation.

Automation & Multi-Processing Solution Zone

We offer a wide range of monitor displays, including case studies of customized automation systems and proposals for optimal multi-function processing machines based on samples of various materials and sheet thicknesses.

Labor-Saving & Productivity Enhancement Support Zone

In this zone, we offer proposals for maintenance and machine modifications to support customers currently using our equipment.

Muratec CCS Co., Ltd.

Dross Removal Tool for Laser Cutting Machines

Slats Dross Cleaner

This tool effectively solves the problem of dross buildup on slats pallets used in laser cutting machines.

Using a chisel-tip impact vibration mechanism, it presses against the spikes to deliver shock and vibration, removing even stubbornly adhered dross.

Its lightweight and compact design makes it easy to handle and ideal for quick, routine maintenance.

Murata Tool Co., Ltd.

DB1000F

The DB1000F offers excellent operability and a variety of disks to remove dross, spatter, and burrs, while also performing chamfering.

By incorporating four rotary sensors into the machine, it instantly measures the height of each disk, ensuring precise and reliable deburring.

Contact

For inquiries about our exhibits and products

at MF-TOKYO 2025,

please feel free to contact us.

All of us at Muratec look forward to welcoming you!

News

Notice of Sheet Metal Solutions Website Migration

We are currently in the process of migrating our Sheet Metal Solutions website to a new platform.

The new site is being prepared to better share information

about our sheet metal division with a wider audience.

We appreciate your continued support of Muratec’s Sheet Metal Division

and look forward to serving you through our renewed website.

Content Overview

We offer a wide range of content, primarily video-based, including product introductions,

customer case studies, and archived webinar recordings.

Stay informed with the latest updates from our sheet metal division.

Processing Videos

Discover Our Product

Lineup Through Video

Explore our wide range of sheet metal solutions—including punch laser combination machines, press brakes, fiber lasers, turret punch presses, deburring machines, and software—through engaging and informative video content.

Hear from Our Customers

Discover how our users are streamlining operations and meeting tight deadlines through the combined power of Muratec’s software and hardware. In these interviews, they share valuable feedback and stories from their experience with our equipment.

Access

Our Webinar Archive

Browse and watch recordings of previously streamed webinars to catch up on valuable insights and product information.

Download

Our Product Catalogs

Access and download PDF versions of our latest product catalogs.

Currently, content is available on our Sheet Metal Solutions Site

prior to the upcoming site migration.

Please note that access to the Sheet Metal Solutions Site requires user registration. We invite you to register using the link below and explore the available resources.